How do you include sustainability targets in your company’s supply chain planning?

4 August 2020

Sustainability is at the top of the agenda in many organisations, and supply chains play a key role in companies’ environmental impact. The climate agenda will require new ways of thinking, and supply chain leaders can make a difference. In this article, we will present our take on how supply chain planning can support companies’ green strategy as well as where and how to get started.

We are facing an accelerating environmental crisis driven by new trends that are changing the way supply chains need to be managed. Climate is at the top of the public agenda, and investors’ interest in green companies is increasing. External stakeholders are demanding companies to deliver more sustainable products and services that contribute to a greener future. Organisations are increasingly met with demands from customers, legislators and investors to account for the impact of their business on sustainability. Many companies have defined sustainability targets as part of their strategy – not only to fulfil consumers’ demands and comply with regulations but also as corporate branding to attract talent, especially young employees.

For many years, supply chains have been optimised for profitability, becoming more cost-efficient and driven by decisions that bring financial value to the company. But today, companies have the opportunity to optimise supply chains for environmental impact as well. Supply chains have a big influence on companies’ environmental effects, representing more than 80% of greenhouse gas emissions for most consumer companies. Many companies are setting sustainability targets as part of the overall strategy, and as a supply chain leader, you have an important role to play!

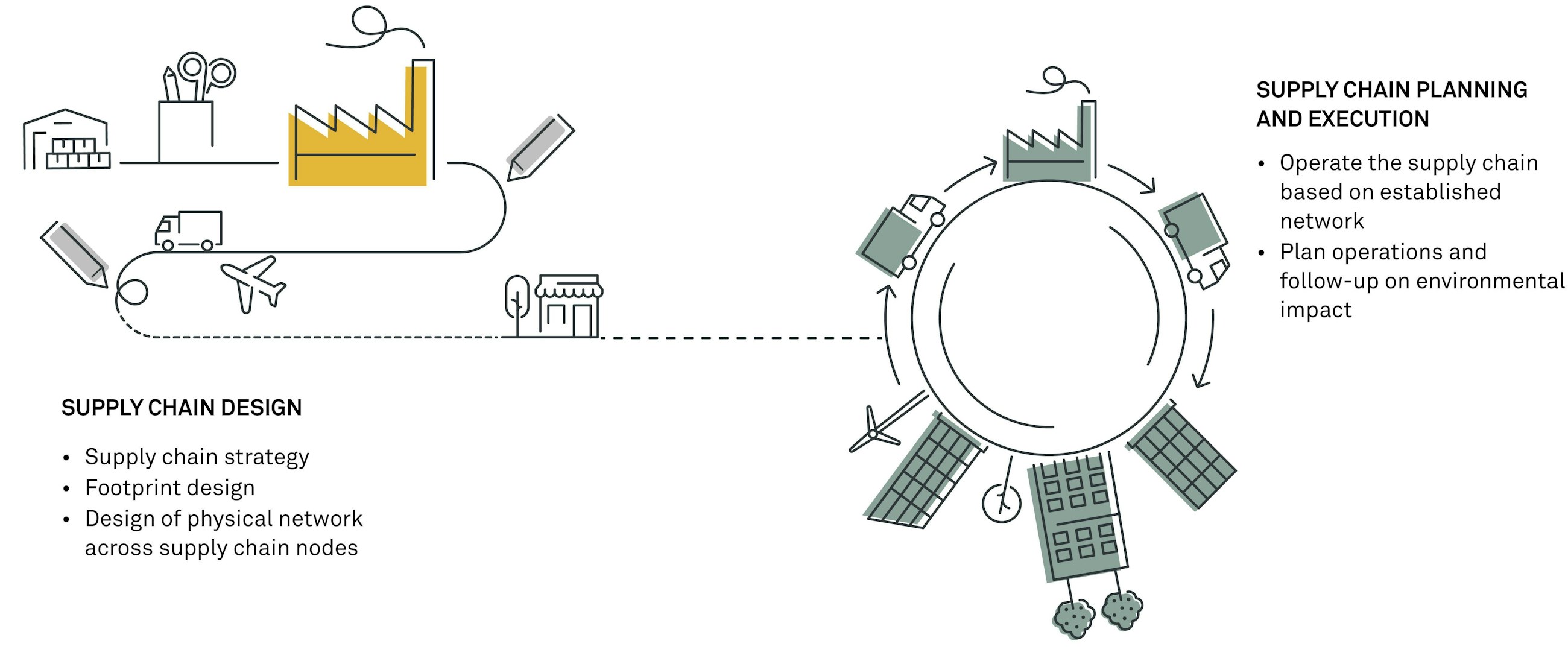

When it comes to supply chain sustainability, we can differentiate between two perspectives: at the strategic level, companies can design their supply chain footprint according to the overall CO2 impact, and at the operational level, companies can plan and execute supply chain operations in an environmentally friendly manner. In this article, we focus on the supply chain planning and execution level by sharing insights into how companies can operate their supply chains in a more sustainable manner and helping to achieve their environmental goals.

Sustainable supply chain planning

The climate agenda is likely to require new ways of thinking, and supply chain planning is not an exception. An evident place to get started is to look into carbon footprint reduction. Once the supply chain footprint is established and the network between suppliers, production sites, distribution points and customers is set, there is an opportunity to optimise the activities for lower CO2 impact. For example, the choice of suppliers or which transport mode to be used has an important impact on carbon emissions. For sustainability to become a driver for planning decisions, it is important to operationalise the company targets and make them tangible to the individual stakeholders in the organisation. That means translating the sustainability goals into targets as is the case with cost or profit targets, which can then be tracked and monitored as part of the supply chain planning process.

When supply chain operations are supported by a strong planning organisation, great opportunities for a company’s emissions reduction arise. The topic of sustainability is often very close to the individual’s values and personal interest, so why not leverage this within your organisation? This can be achieved by enabling each individual to make decisions that contribute to a greener future, thereby anchoring change in the day-to-day supply chain planning activities. For instance, as illustrated below, each individual in the supply chain organisation can take actions that have a direct impact on the planet.

By promoting organisational activism and building on the energy and passion of the individuals, each organisation can make a big difference. From a supply chain planning perspective, every stakeholder involved could positively contribute to the company’s sustainability journey, creating change not only at an organisational level but also on a more personal level.

Where to get started?

Supply chain planning is generally driven by profitability, customer satisfaction and efficiency. We believe that environmental impact must be added to the equation, playing an important role for the decision-making process as part of the supply chain planning activities. We think that carbon measurement is the foundation for accelerating your climate journey, prioritising decisions that really matter and understanding the impact of those.

Transparency is key when it comes to supply chain planning and sustainability in the same manner that cost or profit transparency has driven planning decisions up until today. Being able to assess the CO2 impact of your planning decisions from an end-to-end perspective and having visibility across supplier tiers, stock levels and customers are the starting point for greener planning. Companies need to look at the supply chain environmental impact not only within the boundaries of their own organisation (Scope 1 – Greenhouse Gas Protocol), but they also need to include upstream and downstream activities that have an impact on the planet (Scope 2 and 3 – Greenhouse Gas Protocol). Supply chains today need to be aligned and consolidated across the entire value chain.

Supply chain planning means also cooperating across boundaries by having a dialogue with your suppliers and customers to move towards greener solutions. Prioritising suppliers with green strategies such as green innovation efforts and product development or engaging with clients about how to contribute to their climate goals.

We have seen that transparency is necessary to understand the CO2 impact of the supply chain and to plan accordingly, but how can this be enabled? We need to have systems and tools in place that help us understand how CO2 is associated with our supply chain planning decisions. Digitalisation of the supply chain is needed, and today we have technology available that can help with that.

Technology can enable greener supply chain planning

So, how can we measure how well organisations are doing on their sustainability journey?

In sustainability reporting, a KPI is referred to as a sustainability performance indicator (SPI). SPIs can be used by organisations as a tool to track their business’ sustainability performance to monitor and report on future progress.

The selection of the right and balanced set of SPIs should be a focus for organisations that have sustainability high up on the agenda. In fact, if on the one hand, appropriately selected indicators offer an aid in assessing and tracking an organisation’s sustainability performance, they, on the other hand, help companies communicate and implement their strategies at different levels. Therefore, SPIs must be designed carefully as they can deeply affect the organisation’s strategic, tactical and operational planning.

Once the appropriate set of SPIs is defined, companies need to track them, report on them and follow up on them. This naturally requires technological support.

In the last years, organisations are moving more and more towards digitalisation of processes, and supply chain management is no exception. In today’s volatile economic environment, leading businesses are adopting advanced supply chain planning systems (APS) to make their supply chain planning more efficient, responsive and strategic. So why not leverage this technology to bring sustainability into the planning equation?

As an example, SAP Integrated Business Planning (IBP), the state-of-the-art supply chain planning tool by SAP, could easily support companies in planning for a more sustainable supply chain by e.g. calculating the carbon footprint of the supply plans.

Although, for the time being, no standard functionalities exist in SAP IBP within the area of sustainability planning, this tool provides many opportunities to bring sustainability into the picture.

- It comes with a flexible data model which can be easily customised and made ready to support the sustainability reporting process.

- It supports business partner collaboration to allow the end-to-end visibility over the supply network, which can provide the basis for more informed and sustainable sourcing decisions.

- It allows on-the-fly simulations and scenario planning, which can support evaluating the environmental impact of e.g. choosing different modes of transport.

In addition to this, SAP IBP comes with a user-friendly and intuitive interface: Microsoft Excel, which makes it extremely easy to learn to use.

Different paths, same goal

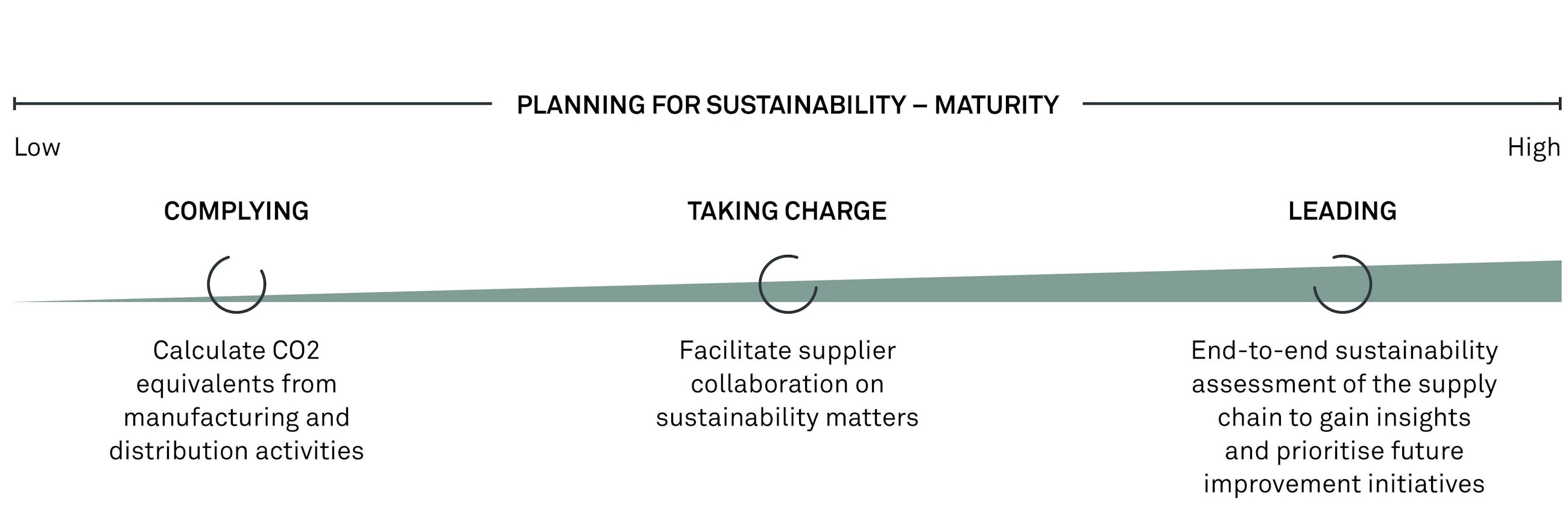

Different companies have different maturity levels when it comes to business processes, and this applies to sustainability too. This being said, any company, whether small or big, having production or just purchasing activities can and should embark on the Planning for Sustainability journey.

Based on the current maturity level and depending on the company’s ambitions to make its operations more sustainable, different initiatives can be implemented.

Companies that are just starting out in sustainable supply chain planning could start small, using existing capabilities and tools to report on the sustainability performance of their supply chain plans. Also, such companies could focus on specific areas within their supply chain: for instance, rather than engaging their entire supply chain, low-maturity organisations could start collaborating with their key direct suppliers.

More mature organisations could go one step further: start using more advanced reporting tools and for example think about including sub-tier suppliers in the scope of their supply chain sustainability initiatives.

Companies that aim at leading the way could do even more: implement robust tracking tools, including IT solutions, to track SPIs and monitor supplier performance and improvement over time; perform an end-to-end assessment of the supply chain to determine where sustainability improvements can be made; integrate sustainability criteria into the procurement process and engage in industry collaboration and multi-stakeholder partnerships particularly to tackle issues too complex to be addressed alone.

As sustainability has become an increasingly important factor for the success of a business, there is a need for companies to set clear and relevant metrics to track their progress and meet the sustainability-related needs of their employees, customers and other stakeholders. Any place is a good place to start, so no matter the maturity level of your company, action must be taken to improve the status quo and progressively extend sustainability goals towards more and more ambitious targets.

Reach out to learn more about how we can assist you with your Planning for Sustainability journey.